It's All in the flow

Viscosity, is the measurement of a fluid’s resistance to flow. A high viscosity in tablet and capsule printing occurs when solvents evaporate from the ink.This can lead to printing imperfections. Our team of engineers was tasked with developing a way of measuring current viscosity during production to ensure consistent and high-quality printing.

The Problem

When our client was running batches of tablets for long periods of time, the temperature and humidity was affecting the ink’s performance. When our engineers made an on-site visit to their production facility to address the issue, they found that even when running small batches the ink was drying far too quickly. This made the transferring of the logo appear blotchy and thus unusable. Noticing that the ink had an almost ‘dripping’ appearance confirmed that the ink’s viscosity needed to be evaluated.

The Solution

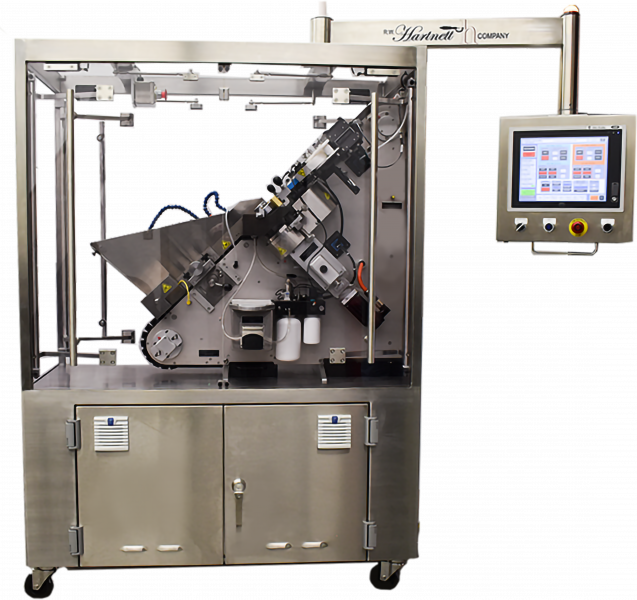

R.W. Hartnett engineers began by pouring the ink into the viscosity system to get an accurate reading of the current viscosity. Our engineers found that by lowering the viscosity in the controlled enclosed system, they were able to maintain a lower viscosity for a longer period of time. This allowed our clients to properly maintain ink viscosity levels that would maintain consistent execution with large batches, over a longer period of time.